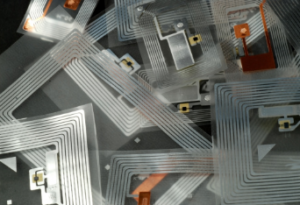

RFID tags are used to track inventory and equipment. This technology provides many benefits, including cost savings and improved customer service. It can also help you meet regulatory requirements.

Reinke says retailers who adopt RFID have reported a higher return on investment than expected. That is because it reduces stock loss and allows for much quicker store stocktakes. For more information about the RFID tags applications australia, click here.

Inventory Management

With their ability to store a large volume of specific data, RFID tags can provide real-time updates about inventory levels. It allows retailers to manage stock better and meet customers’ demands more efficiently.

The technology also makes it easy for staff to complete a stocktake 25 to 30 times faster by replacing manual counting with scanning of tags. It significantly impacts the amount of working capital tied up in inventory and ensures that the right product is ordered to meet demand.

Australian retail brands implementing RFID report more significant profit margins, driven by reducing the working capital in inventory. Ramp works closely with retailers to help them implement this new tech.

Australian retail brands implementing RFID report more significant profit margins, driven by reducing the working capital in inventory. Ramp works closely with retailers to help them implement this new tech.

Asset Tracking

Unlike barcode systems, which require employees to scan each label manually, RFID tags can automatically identify and locate objects. It makes the system more efficient and less prone to errors. Moreover, the data generated can be shared across multiple platforms.

An Australian miner used RFID to automate inventory management at a central warehouse, cutting labour costs and improving productivity. In addition, the technology was able to pinpoint lost equipment.

The Department of Defence is implementing an RFID-based cargo visibility system using commercial off-the-shelf readers from Savi Technology. The system has the potential to be interoperable with allied forces, but this is not yet a reality. It is also being rolled out at air terminals and other points in the supply chain. The system is expected to improve the ADF’s ability to track equipment shipments within Australia and overseas.

Wool Tracking

The Wool Exchange in Tasmania uses RFID to track each wool bale from the paddock to the store. The system uses a QR code and microchip to link each pack with the grower, place of origin, wool quality test results and farm number. This information can then be viewed on a smartphone app or website.

The system uses fixed RFID readers arranged in portal configurations and mobile readers. The tags are active, with a battery to power their return reporting signal. It allows a tight reading zone to be defined.

Ramp says retailers should understand that RFID helps them cut costs, improve customer experience and grow sales. It also prevents loss and enhances efficiency. The company predicts that item-level tagging will overtake pallet and case tagging, which delivers excellent paybacks.

Healthcare

RFID (radio-frequency identification) technology is now widely used in agriculture, manufacturing, supply chain and transportation. But healthcare is another area where it could have a significant impact. Medical errors can take a huge toll on public health, and hospitals and healthcare facilities need to streamline processes.

Using RFID tags to track equipment can help reduce the number of errors. For example, staff can quickly locate a missing nurse’s trolley or medication cart by scanning the room. In addition, RFID can monitor temperature and humidity in surgical areas. For more information about the RFID tags applications australia, click here.

The Department of Defence is implementing RFID in its supply chains, with fixed readers in portal configurations at warehouses and air terminals. The agency has chosen to use a military-off-the-shelf system from Savi Technology, which is interoperable with allied forces.

Security

RFID is a well-known wireless technology omnipresent in everyday life (tickets, payment systems, passports, car immobilisers). It has become a key driver for cargo visibility and supply chain management innovations.

The technology is gaining traction in retail stores nationwide, with several large chains now introducing it to their stores. Reinke says that retailers who adopt the system report that it cuts costs, grows sales, and virtually eliminates stock loss.

Passive RFID solutions and labels are cost-effective, as the tags do not need an internal battery. However, active RFID solutions provide greater read ranges and allow for telemetry inputs for sensory systems. They also offer a more robust solution for high-temperature and extreme environments.

Our Modbury, Adelaide dental clinic uses CEREC technology to digitally scan and fabricate your crown restoration in a single visit. It means fewer injections and less time in the chair! For

Our Modbury, Adelaide dental clinic uses CEREC technology to digitally scan and fabricate your crown restoration in a single visit. It means fewer injections and less time in the chair! For  Having a beautiful smile has a positive impact on a patient’s life. Here are five benefits of having a cosmetic dentistry treatment carried out. GlamSmile porcelain veneers are fragile and can be bonded to natural teeth without cutting back any healthy tissue.

Having a beautiful smile has a positive impact on a patient’s life. Here are five benefits of having a cosmetic dentistry treatment carried out. GlamSmile porcelain veneers are fragile and can be bonded to natural teeth without cutting back any healthy tissue. Before selecting a furniture removalist Adelaide company for your move, ask about their experience and equipment. It is essential that they can handle every step of your relocation safely.

Before selecting a furniture removalist Adelaide company for your move, ask about their experience and equipment. It is essential that they can handle every step of your relocation safely. Heels are an effective way to add height and elevate any outfit, be it on a first date or to make someone particular feel extra special. If that means making sure they feel special, too, heels may be necessary!

Heels are an effective way to add height and elevate any outfit, be it on a first date or to make someone particular feel extra special. If that means making sure they feel special, too, heels may be necessary!